Protecting Concrete from Chloride Ion Diffusion

One of the leading culprits of concrete highway damage is chloride ion diffusion. This is most often a result of deicers applied to highways, meant to keep roads safe from snow and ice. Common deicers such as Calcium Chloride (CaCl2), are effective at melting ice and snow at lower temperatures. However, CaCl2 doesn’t go away after the ice melts.

While deicers are primarily used in the winter months to keep pavements safe for travel, these chemicals are absorbed, and ions diffuse into the pore network of concrete where they build up over time. In the warmer temperatures of spring, summer and fall months, these ions react with the calcium hydroxide that exists in the pores of all concrete. This reaction forms a product called calcium oxychloride, which expands and causes damage year-round.

For a decade, the Wisconsin Department of Transportation (WisDOT) has been applying various penetrating sealers like silanes, siloxanes and others to the saw-cut faces of concrete pavement joints. These products are meant to improve pavement joint performance by reducing fluid absorption and minimizing ionic diffusion. Until recently, however, there was little data proving these penetrating sealers were protecting joints.

To measure the effectiveness of different treatments, WisDOT funded a comprehensive study to analyze the protection of concrete joints in highways. Its findings were released in March 2020.

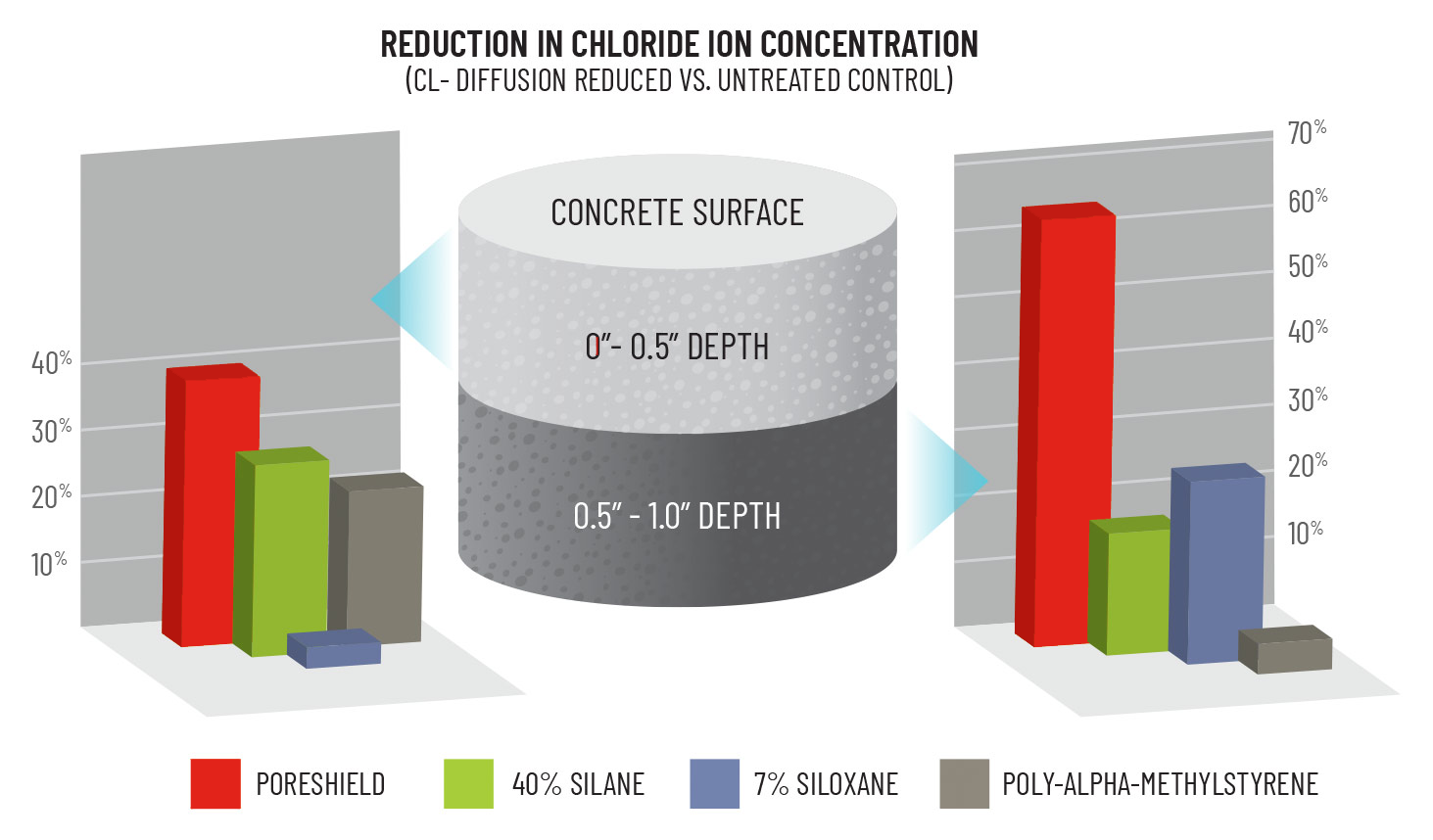

WisDOT evaluated seven products: standard penetrating sealers (versions of silane, siloxane, poly-alpha-methylstyrene and lithium silicate) and PoreShield. The study demonstrated that PoreShield was more than twice as effective as the penetrating sealers at reducing chloride ion diffusion when measured at least 0.5 inches below the surface.

Because PoreShield fills the concrete pores, it blocks the absorption and diffusion of ions and keeps damaging ions such as CaCl2 at the surface. This deters many forms of damage, including the formation of calcium oxychloride, reducing long-term damage from salt in all seasons.

PoreShield protects new and old concrete from premature damage that begins on the inside, caused by fluid absorption, deicing chemicals and freeze/thaw conditions. PoreShield is often compared to conventional penetrating sealers because both are applied topically and absorb into concrete. However, PoreShield performs very differently. It is a long-term durability enhancer that fills pores instead of merely coating them. When conventional sealers inevitably begin to crack, they allow moisture to seep in, carrying salt into the concrete structure and trapping it there. But PoreShield stays fluid, so it won’t crack.

- It does not undergo a chemical reaction, solidify or form crystals

- It remains fluid and does not leave any film on the surface.

- It creates a flexible, self-healing, hydrophobic barrier that continues to protect even after concrete cracks.

- It is a durability enhancer when applied in admixtures as well.

- PoreShield does not need to be reapplied for 10 or more years.

In addition to being high performance, PoreShield is renewable and sustainable – derived from soy with a 93% bio-content. Its non-toxic profile provides confidence in safety for workers and the environment.

PoreShield can be used on all densities of concrete whether vertical or horizontal, and in many applications including highways, bridges, precast and other structures.

This research was funded through the Wisconsin Highway Research Program by the Wisconsin Department of Transportation and the Federal Highway Administration.

Get in touch for to see how PoreShield can help protect your next concrete project.